What Is Pyrolysis?

The Science Behind Turning Waste Into Energy

Pyrolysis is an advanced thermochemical decomposition process in which organic or carbon-based materials are heated in high temperatures in the absence of oxygen. Without oxygen, the materials do not burn, instead, chemical bonds break down forming the materials into simpler molecules. During pyrolysis, the material decomposes into three main products: solid char, liquid bio-oil, and gaseous syngas. Since pyrolysis can convert waste into valuable resources, industries and governments are exploring its potential as a sustainable alternative to landfilling and incineration, emerging as a solution in waste management, renewable energy, and circular economy systems.

This article explores the terminologies and technologies to give an understanding regarding the pyrolysis process, illustrating the different types of pyrolysis, as well as different feedstocks and pyrolysis end-products. At Qlean Tech, we leverage this technology to help industries and research institutions convert waste into valuable resources, supporting sustainable waste management, renewable energy production, and circular economy initiatives. Our full-suite EPCC services ensure that clients can implement end-to-end pyrolysis systems that maximize resource recovery and environmental benefits.

Type of Pyrolysis (Biomass, Rubber, Oil)

Pyrolysis is not a uniform process, it can encompass a wide range of technology that vary depending on operating conditions, feedstock, and desired end product. Therefore, pyrolysis is generally classified based on several key criteria, each influencing the system designs, efficiency and output composition.

In real-world applications, pyrolysis is often discussed by feedstock as it directly determines system design, product output, regulatory requirements and overall economic viability.

Biomass Pyrolysis

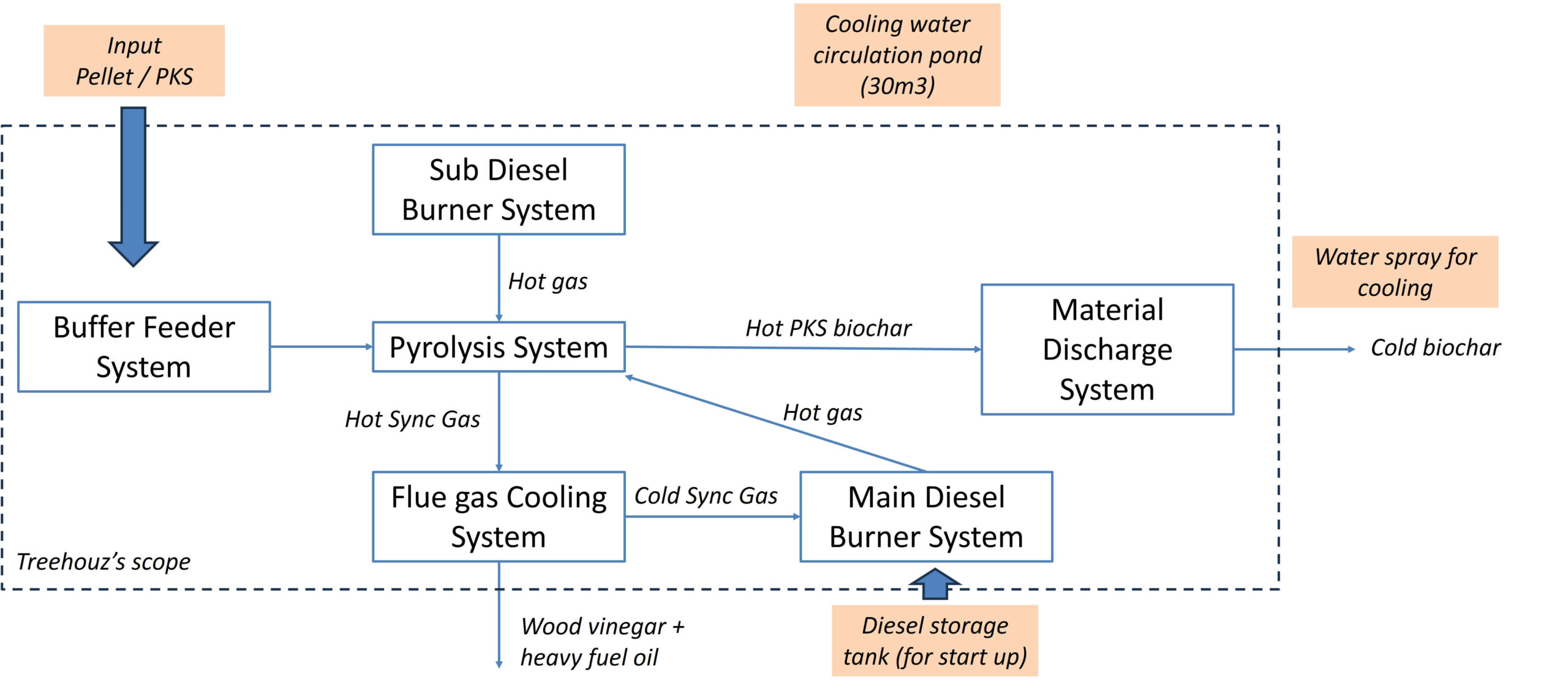

Biomass pyrolysis is the thermal decomposition of organic materials such as wood, crop residue like coconut shell, sawdust, palm oil residues like empty fruit bunches (EFB) and palm kernel shells (PKS), and agricultural waste. In this process, organic material is heated at elevated temperature in the minimal presence of oxygen, producing energy carriers including biochar, heavy fuel oil (pyrolysis oil), and light fuel oil (wood vinegar). Depending on the desired outcome, the process can be optimized — through slow, fast, or flash pyrolysis — to maximize the production of specific carriers, such as biochar.

It is a key technology for converting agricultural residues, forestry waste, and algae into high-value liquid, solid, and gaseous products. It plays a critical role in reducing waste volumes, preventing open burning or landfill accumulation while generating value-added products, circling economy initiatives. Unlike any mechanical recycling or specific fermentation process, biomass pyrolysis handles a diverse range of materials making it highly adaptable across regional and industrial needs.

Rubber Pyrolysis

Rubber pyrolysis is a key process for managing rubber waste, particularly scrap tires, which pose significant environmental hazards because they are non-biodegradable, flammable and toxic. In rubber pyrolysis, waste tires or rubber materials are heated at high temperature (400°C – 600°C) in an oxygen-free environment, causing long polymer chains to break down into valuable byproducts mainly including tire pyrolysis oil, recovered carbon black (rCB), steel wire, and syngas.

One of the key advantages that rubber pyrolysis brings is its high recovery rate. This means that instead of destroying the material, pyrolysis preserves and recovers the valuable components from tires with minimal emissions generated, making the process environmentally and economically attractive. Therefore, rubber pyrolysis plays an important role in terms of environmental sustainability and circular economy by converting hazardous waste trouble into energy and materials.

Oil Pyrolysis

Oil pyrolysis is the thermal decomposition of oil-based waste such as used motor oil, industrial oily sludge, refinery residue, and drilling waste. This process is an effective way in treating hazardous oil-containing materials while at the same time recovering valuable resources. In oil pyrolysis, oil-based waste is heated to high temperatures inside a sealed reactor. The heat and lack of oxygen breaks down hydrocarbon chains into smaller molecules, dividing the materials into recoverable oil, combustible gas and solid residue.

This process offers a sustainable solution for oil and gas industries, playing a significant part in environmental protection by preventing hazardous materials from entering into landfills or water bodies, avoiding the contamination of soil and groundwater. Materials produced from the process such as syngas can be recycled to supply heat to the reactor, making it a self-sustaining energy loop that improves efficiency while supporting environmental protection and circular waste management.

Pyrolysis Process Explained

Feedstock Preparation and Handling

Prior to processing, feedstock materials (plastic, rubber, biomass, oil-sludges, mixed waste, etc) are sorted, mechanically reduced to smaller sizes (5-50mm), depending on reactor design through shredding or crushing. Wet materials will be dried (to <10% moisture) as moisture levels directly impact energy demand. Such preparation is critical to ensure rapid and uniform heating.

Oxygen-Free Heating in Reactor

Prepared feedstock is fed into a sealed pyrolysis reactor that operates under oxygen-free or inert conditions. Nitrogen is often used in lab scale to purge oxygen at the start. Heating rates vary from 1°C-10°C/min in slow pyrolysis to >100°C/s in fast or flash pyrolysis, depending on preferable results.

Thermal Decomposition of Materials

As temperature increases, the feedstock undergoes endothermic thermal decomposition, a process where material breaks down when heat is absorbed from an external source. Polymer chains and organic structures break into smaller molecules. Volatile matter will be released in the form of gases and vapour, while fixed carbon and inorganic materials remain as solid residue.

Vapor Cooling and Product Separation

Hot vapours exiting the reactor are cooled down in condensers operating between 50°C-80°C, where condensable compounds will form liquid products. Non-condensable gases are collected as syngas, solid residues will remain in the reactor and are discharged after cooling.

Energy Recovery and Reuse

Syngas normally has lower heating values (10-25MJ/Nm³), depending on the composition. In many commercial systems, 60%-100% of the reactor’s heat demand can be fulfilled by recycling syngas, significantly reducing external fuel requirements.

From Waste to Wealth: Pyrolysis Products

Pyrolysis converts organic or carbon based feedstocks into a combination of solid, liquid, and gaseous products, each with distinct applications depending on the feedstock and operating conditions.

Solid Products

For biomass pyrolysis, the solid outputs commonly include biochar, activated carbon, and charcoal briquettes, which are widely used across agriculture, environmental remediation, and energy sectors. In the case of rubber pyrolysis, the main solid product is recovered carbon black (rCB), which sees significant reuse in rubber manufacturing, plastics production, and construction materials. Oil pyrolysis, on the other hand, typically generates a carbon-rich solid residue or coke, often used as a supplementary fuel source or in other industrial applications.

Of these solid outputs, biochar stands out as one of the most significant products of biomass pyrolysis. Biochar is a highly carbon-dense solid residue, containing 50-90% carbon. This high carbon content makes it invaluable for enhancing soil fertility, improving water retention, and crucially, sequestering carbon in the soil for decades, making it a great tool in sustainable agriculture and carbon sequestration. Slow pyrolysis is an effective method for maximizing biochar production, capable of yielding 15-30% biochar by weight of the original biomass.

Activated carbon is a highly porous, processed form of carbon produced by further treating carbonized precursor materials under activation conditions that develop extensive microporosity. It is produced through further treating biochar with steam, carbon dioxide, or chemical activators at high temperatures. This activation produces a very high surface area — with typical commercial activated carbons having surface areas often in the hundreds up to over a thousand square metres per gram — making them effective adsorbents. It is often used for water purification, air filtration, and industrial chemical processes.

Charcoal briquettes are made by compressing charcoal or pyrolyzed biomass particles with binders into uniform blocks or briquettes that serve as solid fuels.Because they are densified and partially carbonized, these briquettes provide consistent energy output and generally burn with lower smoke emissions compared with burning raw wood. They are normally used as efficient cooking fuel and heating materials.

Liquid Products

Liquid products are a major output of pyrolysis, formed when volatile compounds released during thermal decomposition are cooled and condensed. These liquids vary significantly depending on feedstock type and operating conditions. In biomass pyrolysis, liquid products primarily include bio-oil and wood vinegar, both are derived from the condensation of organic vapors released from plant-based materials. Rubber pyrolysis produces tire pyrolysis oil, often referred to as light pyrolysis fuel oil when used as an alternative industrial fuel, it is widely used as a liquid fuel for boilers, cement factories, steel factories, etc. In oil pyrolysis, liquid output is usually referred to as recovered oil, it can vary in composition depending on the type of oily waste treated, operating temperature, and process configuration.

Pyrolysis Bio-oil is a complex, dark brown liquid consisting of oxygenated hydrocarbons, water and other organic compounds. It can be used as industrial fuel that is refined into diesel or gasoline, or even serve as a feedstock for chemical production. Pyrolysis oil yields vary widely, typically 35–70% by weight depending on feedstock and operating conditions.

Wood vinegar, also known as pyroligneous acid, is a dark liquid produced by the destructive distillation of wood and other plant materials, its principal components consist of acetic acid, acetone and methanol, which are obtained from biomass pyrolysis. Wood vinegar typically contains more than 200 different organic compounds, and is commonly used as a natural pesticide, growth promoter, and soil conditioner.

Gaseous Products

Pyrolysis processes generate a valuable gaseous product stream, commonly referred to as pyrolysis gas or syngas, across biomass, rubber, and oil-based feedstocks, consisting mainly of combustible and non-condensable gases formed under oxygen-limited conditions

In biomass pyrolysis, the gaseous fraction typically contains hydrogen (H₂), carbon monoxide (CO), carbon dioxide (CO₂), methane (CH₄), and light hydrocarbons such as ethylene (C₂H₄) and ethane (C₂H₆), with gas composition strongly influenced by feedstock type and operating temperature. These gases are often reused on-site to provide process heat or electricity, improving the overall energy efficiency and energy self-sufficiency of biomass pyrolysis systems.

When the gaseous stream contains significant proportions of hydrogen and carbon monoxide, it is commonly referred to as syngas, which serves as a key intermediate for energy conversion and chemical synthesis processes. Syngas produced from pyrolysis can be further upgraded through gas cleaning and conditioning steps, including tar removal and reforming, to improve its calorific value and compatibility with downstream technologies.

How pyrolysis differs from Incineration, Gasification, Composting

Pyrolysis is frequently grouped with other waste treatment methods, yet its operation is fundamentally different. Unlike burning, pyrolysis processes materials by heating them in the absence of oxygen. This action breaks the feedstock down into smaller particles, which are the valuable products of the process, such as fuels, chemicals, and solid carbon materials. In contrast:

- Incineration involves burning waste with excess oxygen, converting it into heat, flue gases, and ash, with very limited material recovery.

- Gasification uses a small, controlled amount of oxygen or steam at high temperatures to produce syngas, yielding few liquid or solid by-products.

- Composting is a biological process reliant on microorganisms and oxygen to slowly decompose organic waste over time, producing compost rather than energy or fuels.

Therefore, pyrolysis is unique among these technologies for its ability to simultaneously recover valuable fuels, chemicals, and solid carbon materials without burning any feedstock.

| Process | Pyrolysis | Incineration | Gasification | Composting |

|---|---|---|---|---|

| Mechanism / Oxygen Requirement | Thermal decomposition in the absence of oxygen | Combustion in excess oxygen | Partial oxidation with limited oxygen or steam | Biological decomposition by microorganisms in oxygen |

| Outputs / Products | Biochar, bio-oil, syngas | Heat, flue gases, ash | Syngas (H₂ + CO) | Compost |

| Energy Recovery | High | High (heat) | Medium | None |

| Material Recovery | High | Very limited | Low | High (nutrient-rich) |

| Notes | Breaks down feedstock into useful solid, liquid, and gas without combustion | Mainly generates heat; material recovery is minimal | Produces mainly gas; few liquid or solid products | Biological process; produces soil amendment instead of fuel or energy |

Pyrolysis in Malaysia: ESG, Carbon Credits, and Policy Readiness

Across Malaysia and Southeast Asia, governments and corporations are increasingly aligning with Environmental, Social, and Governance (ESG) priorities to support emissions reduction and long-term sustainability goals, including net-zero commitments. In Malaysia, a key measure in this effort is the recently announced carbon tax, set for implementation in 2026, which targets high-emission sectors and encourages the adoption of cleaner technologies.

Pyrolysis offers a strategic solution for companies, particularly those in the agricultural and plantation sectors, by transforming organic waste into valuable by-products such as biochar, bio-oil, and syngas. This process effectively minimizes waste, lowers greenhouse gas (GHG) emissions, and supports circular economy goals, as the biochar produced can sequester carbon in soils for decades. This not only helps companies offset emissions but also prepares them for compliance with Malaysia’s forthcoming carbon tax or carbon pricing mechanisms.

From a carbon market perspective, certified biochar-based pyrolysis systems can qualify for internationally recognised carbon credits under established frameworks such as Verra and Puro.earth, subject to strict requirements on additionality, monitoring, verification, and long-term carbon storage. As Malaysia develops its national carbon market framework, these global standards provide an immediate pathway for companies to participate in high-integrity voluntary carbon markets.

At Qlean Tech, we support organisations in deploying industrial-grade pyrolysis systems that align with ESG objectives, carbon reduction strategies, and emerging regulatory requirements. Through end-to-end engineering, project delivery, and collaboration with experienced technical and verification partners, Qlean Tech helps clients translate waste management challenges into measurable carbon and sustainability outcomes. Contact us to find out more!

Frequently Asked Questions (FAQs)

What is pyrolysis?

Pyrolysis is a thermochemical process in which organic or carbon-based materials are heated in the absence of oxygen. Instead of burning, the materials decompose into three main products: solid char, liquid oil, and gaseous syngas. Pyrolysis is widely used in waste management, renewable energy production, and circular economy applications.

How is pyrolysis different from combustion or gasification?

Pyrolysis occurs without oxygen and produces char, oil, and syngas. Combustion burns materials with excess oxygen to produce heat and emissions, while gasification uses limited oxygen or steam to mainly produce syngas with minimal solid or liquid outputs.

What materials can be processed through pyrolysis?

Common feedstocks include biomass (such as wood waste, palm residues, coconut shells, and agricultural by-products), rubber waste (especially scrap tires), plastics, and oil-based waste such as oily sludge or used industrial oils. Feedstock characteristics strongly influence system design, product yields, and regulatory requirements.

What are the main products of pyrolysis?

Pyrolysis produces a combination of solid, liquid, and gaseous outputs:

- Solid: biochar, recovered carbon black, or carbon-rich residue

- Liquid: bio-oil, wood vinegar, tire pyrolysis oil, or recovered oil

- Gas: syngas containing combustible gases such as hydrogen, carbon monoxide, and methane

The proportion of each product depends on feedstock type and operating conditions.

What temperatures are typically used in pyrolysis?

Pyrolysis generally operates between 300°C and 700°C, depending on the feedstock, reactor design, and desired end products. Rubber and oil-based feedstocks usually require higher temperatures than biomass.

Does pyrolysis reduce waste volume?

Yes. Pyrolysis can significantly reduce waste volume by converting most organic material into useful energy products and solid carbon, leaving only a small fraction of residual solids compared to landfilling or incineration.

Is pyrolysis environmentally friendly?

When properly designed and operated, pyrolysis avoids direct combustion, reduces greenhouse gas emissions, and enables material and energy recovery from waste. The reuse of syngas for process heat and the long-term carbon storage potential of biochar further enhance its environmental performance.

Is pyrolysis economically viable?

Pyrolysis can be economically viable, particularly when integrated with energy recovery, material reuse, or carbon credit schemes. Economic performance depends on plant scale, feedstock availability, product utilisation, and regulatory incentives.

What are the main challenges of pyrolysis?

Key challenges include feedstock variability, upfront capital costs, system optimisation, and maintaining consistent product quality. These challenges can be addressed through proper engineering design, feedstock preparation, and operational control.

Is pyrolysis safe?

Yes, when operated under controlled conditions and in compliance with environmental and safety regulations. Industrial pyrolysis systems require proper engineering, monitoring, and trained operators to ensure safe and stable operation.

What permits are required for a pyrolysis plant in Malaysia?

Permits typically include environmental approvals such as an Environmental Impact Assessment (EIA), waste management licences, and approvals from relevant authorities. Requirements vary based on feedstock type, plant capacity, and project location.

Can pyrolysis projects generate carbon credits?

Pyrolysis projects that produce biochar for long-term carbon sequestration may qualify for carbon credits under recognised international standards such as Verra and Puro.earth, subject to strict requirements on additionality, monitoring, verification, and durability of carbon storage. Eligibility depends on project design and compliance with approved methodologies.

What role does pyrolysis play in a circular economy?

Pyrolysis converts waste into valuable fuels, chemicals, and carbon materials, reducing reliance on landfills and fossil resources while supporting closed-loop material and energy systems.

What innovations are emerging in pyrolysis technology?

Recent developments include catalytic pyrolysis, advanced reactor designs, improved gas cleaning systems, and integration with renewable energy and carbon capture technologies to enhance efficiency and sustainability.

How long does it take to build and commission a pyrolysis plant?

Project timelines vary depending on plant capacity, technology selection, and permitting complexity. Typical phases include feasibility assessment, engineering and design, procurement and fabrication, construction, commissioning, and performance testing. End-to-end projects can range from several months to over a year. At Qlean Tech, we offer complete EPCC services for biomass pyrolysis — contact us to learn more.

EPCC Services for Biomass Pyrolysis Systems

Qlean Tech is a trusted leader in sustainable biomass pyrolysis technology, with over 20 years of experience in research, development, and innovation. We help industries unlock value from waste through advanced thermochemical conversion.

At the core of Qlean Tech’s offerings is our Engineering, Procurement, Construction, and Commissioning (EPCC) service, providing full lifecycle support for biomass and waste-to-energy projects — from initial design and engineering to system build, installation, and operational commissioning — enabling industries, research institutes, and strategic partners to deploy reliable, scalable biomass pyrolysis plants with confidence.

Beyond system delivery, we also support feasibility studies, system optimisation, and sustainability alignment, helping clients improve overall operational efficiency while reducing environmental impact.